Relocatable Site Solutions

Quality site solutions for seamless operations.

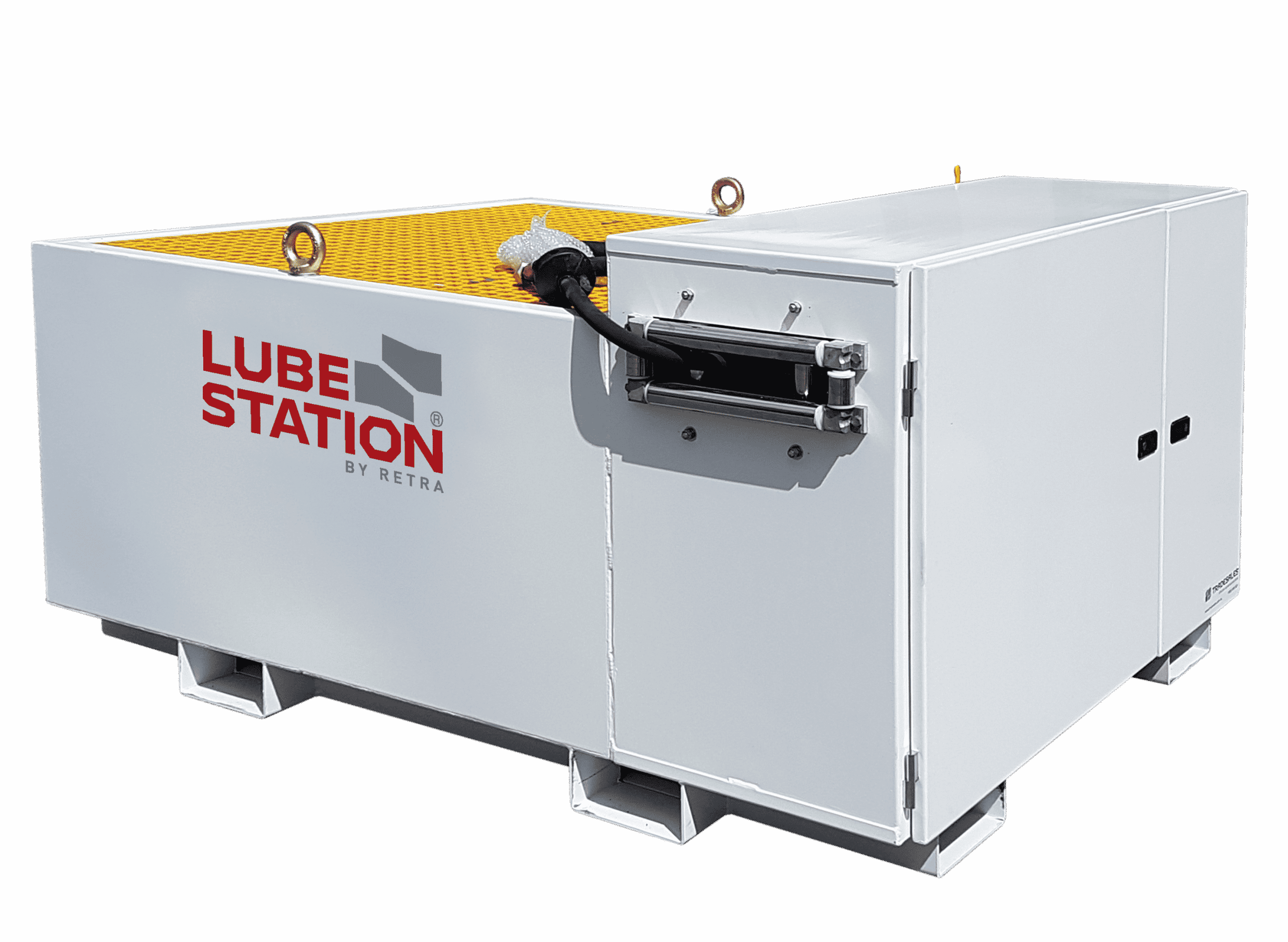

Lubestations

Lubestations can be grouped into four categories based on their purpose – mobile equipment, fixed plant, workshop, and skid. While some of these Lubestations may not look all that different from the outside, they each have unique features that separate them, making them ideal for the task.